BB Tools

BB Rotary Broach Hexagon -HSS-PM

BB Rotary Broach Hexagon -HSS-PM

Couldn't load pickup availability

Share

Selected High-Quality Steel Corrosion Resistance and Wear Resistance

Improving the overall wear resistance and toughness of cutting tools to extend their service life

Punch Out the Inner Hexagon in One Process

Broaching tool is a simple cutting tool, which can be split into regular or irregular polygons on blind holes or through holes, sharp edges or chamfering edges, in addition to standard hexagonal and square holes, they can also be used as grooves, stars or other special shapes.

High Precision High Efficiency One-Time Molding

Feed 0.03-0.06mm per revolution, copper aluminum processing 2-3 times efficient and fast, with one hole per second

Recommended Processing Equipment

Suitable for general lathes, CNC automatic lathes, comprehensive processing machines, drilling machines and machines with special functions. It is also suitable for punching various standard or special internal and external holes.

Case Presentation

Installed On The Machining Center

Example: Machining spline m=1z=16 deep 20mm

1. Speed: S=1000r/min

2. Feed: F=20m

3. Processing time: 3 minutes (divided into multiple cuts)

Installed on the Lathe

Example: Processing hexagonal 10 with a depth of 15mm on opposite sides

1. Speed: S=1000/min

2. Feed: F=40mm/min

3. Processing time: 20s

Note:

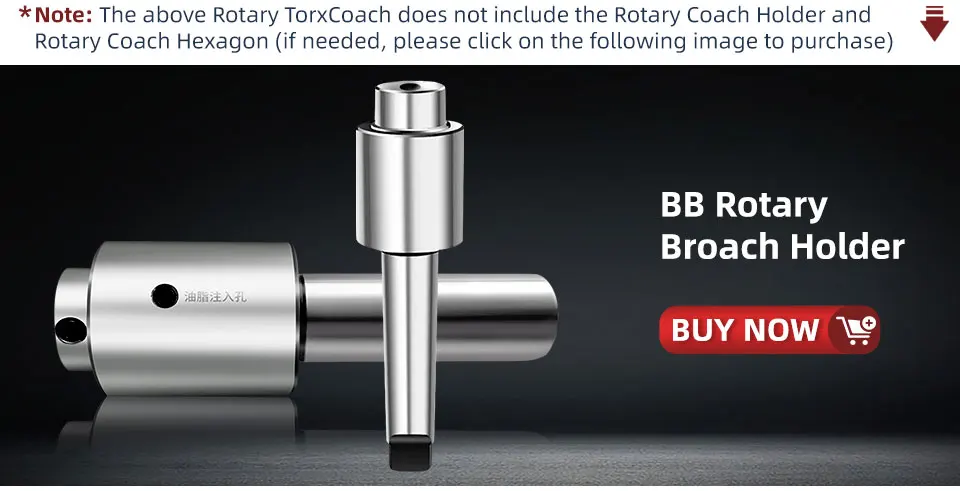

The above Rotary TorxCoach does not include the Rotary Coach Holder and Rotary Coach Hexagon (if needed, please click on the following image to purchase)

Rotary Torx Broach

BB Hexagon Rotary Broach

Broaching tool is a simple cutting tool, which can be split into regular or irregular polygons on blind holes or through holes, sharp edges or chamfering edges, in addition to standard hexagonal and square holes, they can also be used as grooves, stars or other special shapes.

Suitable for general lathes, CNC automatic lathes, comprehensive processing machines, drilling machines and machines with special functions. It is also suitable for punching various standard or special internal and external holes.

Material

①HSS-Co M35

②HSS-Powder metallurgy high speed steels

③Tungsten Carbide

*Some sizes need to be customized in about a week

1/16''=1.62 , 1/8''=3.26 , 3/8''=9.6

Drill Hole

The normal drilling of the hexagonal hole must be slightly larger than the effective size of the two-phase plane to which the hole is broached.

Hex S=6~10mm, allowable tolerance +0.06~+0.12mm

Generally, we suggest that the depth of drilling is 1.3 to 1.5 times of the depth of broach hole.

Rotating speed

The principle of BB rotary broach allows it to be applied to high rotating speed, from 600 to 2000 r/min minutes, because rotary speed does not affect the cutting speed. However, at very high speed, when the processing starts, the punch will rub with the workpiece until the speed is synchronized. In this way, it is very easy to wear out the punching knife in advance when using the small punching knife frequently. In order to avoid this phenomenon, it takes 500 r/min minutes at the beginning and the feed is 0. 1mm/turn, when the punch enters the working state, increase the rotation speed.

Feed

The selection of feed is based on the characteristics of the material. In medium carbon steel, if the machine has enough thrust, we suggest that the feed rate of each feed is 0.03~0.06mm. In copper and aluminum materials, two or even three times of the feed volume can be used. In the processing of large axle size and hard-to-cut materials, the feed rate must be reduced by 0.01mm.

Through Hole and blind hole

Generally, there is no need to consider the problem of chip removal when passing through the hole, as long as the depth is noted and the punch is long enough to be customized.

After the blind hole is reserved enough depth, the hexagonal hole should be punched. After the hexagonal hole is finished, the inner hole should be drilled with the drill bit of the previous base hole to discharge the residual debris. Note that the drill bit should be at least 0.1mm smaller than the side of the hexagon, and it cannot touch the inner wall of the hexagon when drilling chips.

BB Rotary Broach Holder

HI, welcome to BB official store.

-We are professional manufacturer ,development and production of machining tools.

-We provide various tools for you . You can follow us and see more.

-You have free choice of collocation, pick different specifications and other tools in our store to you cart and pay them together. We will send the products you have picked as a package.

SHIPMENT

-We have already paid 80% of delivery cost .

-Orders processed timely after the payment verification.We ship products within 3 working days.

-The trade is cross-border, and Airmail is cheapest post which take a long time for delivery.If you need the item urgently ,please choose Express way.

-If you have not received your shipment within 60 days from payment, please contact us. We will track the shipment and get a reply to you as soon as possible.

We sincerely hope that BB tools will meet your full requirements. Please enjoy your online shopping.