BB Tools

Saw Blade Circular Milling Cutting Disc Tool CNC Slot Machining Tungsten Carbide Steel Diameter 110mm Slitting Metal Steel

Saw Blade Circular Milling Cutting Disc Tool CNC Slot Machining Tungsten Carbide Steel Diameter 110mm Slitting Metal Steel

Couldn't load pickup availability

Share

Saw Blade (1PCS)

☆NOTICE: Required to use with the toolholder which is NOT INCLUDED in this link, please click on the image below to purchase if needed.

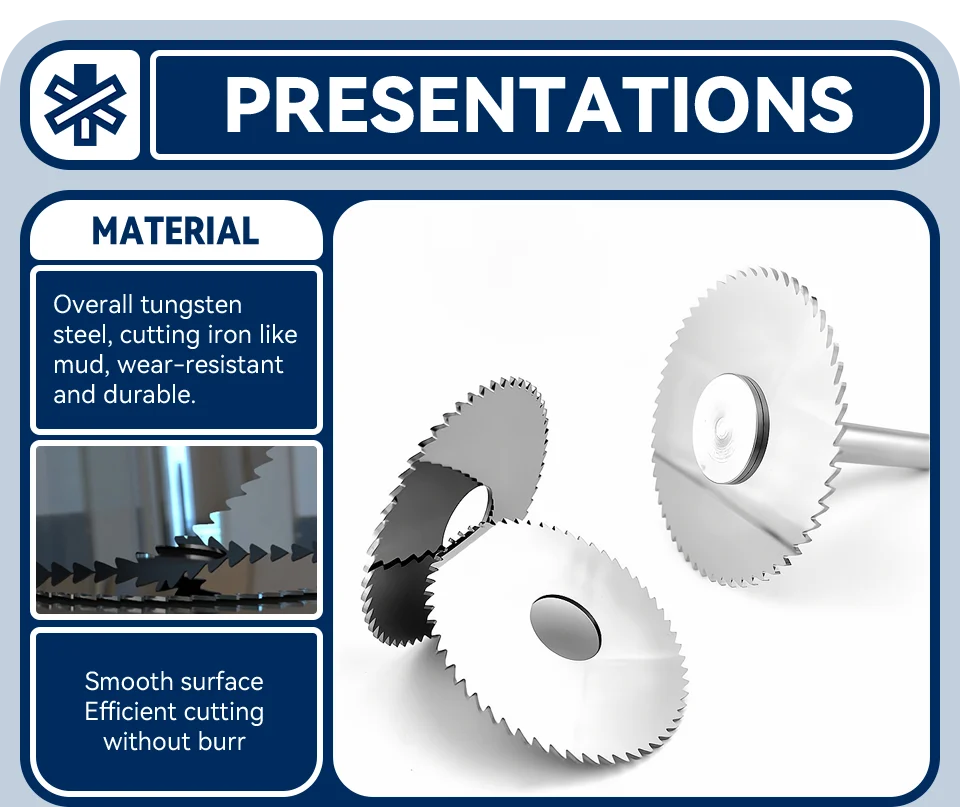

☆Material:

Overall combined with full tungsten steel, cutting iron like mud, using special steel lattice mixed processing, shock-resistant wear-resistant high temperature resistance, long life.

Double-sided high-gloss mirror effect, good glossiness. Overall leveling design, smooth surface, smooth and efficient cutting.

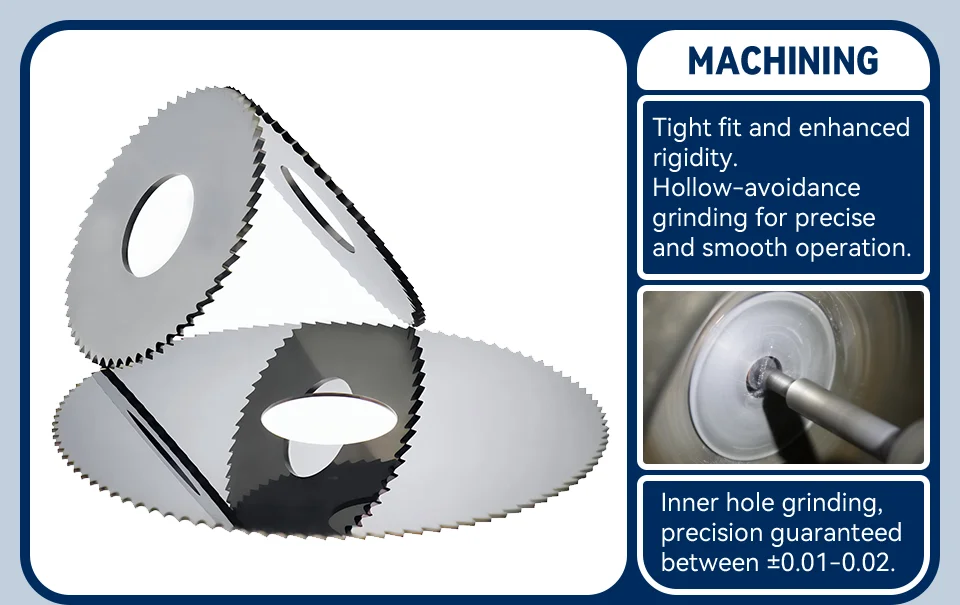

☆Processing:

Precision:

Inner hole——+0.01~0.02

Outer——±0.02

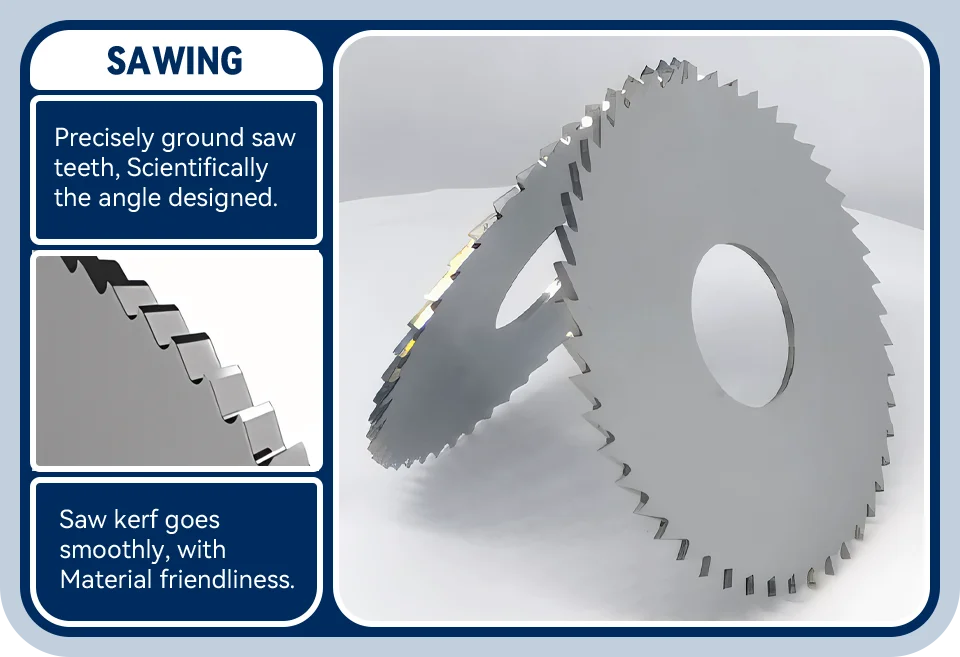

☆Sawing:

Saw teeth precision grinding processing, angle scientific design, sharp, smooth machining, no burn board, no roll edge, no burr.

The thinner the saw blade is, the more sensitive it is to vibration and tensile stress when using it. If there is radial runout or axial runout, it is easy to cause damage.

Bad. Therefore, the milling machine should operate in a stable state, that is, the machine tool has high precision, good rigidity of cutter bar and stable transmission. Feed quantity per tooth

Constant and sufficient cooling. The specific requirements are as follows:

1. The accuracy of the milling cutter installed on the cutter Rod shall generally meet the following requirements: radial runout <0.02mm, axial runout ≤ 0.01mm.

2. As long as the milling depth of the milling cutter is not affected, clamp the two sides of the blade on the cutter rod with a large flange plate as much as possible, in order to eliminate vibration and avoid lateral compression. Generally, the diameter of the flange plate is not less than 1/3 of the outer diameter of the saw blade.

3. Reasonable milling linear speed Vc and feed rate Sz per tooth should be selected. Generally, under the same conditions, the whole hard alloy saw blade milling cutter can choose Vc faster than the high-speed steel saw blade milling cutter, but the feed rate per tooth should be lower than the feed rate of high-speed steel. Sz can generally be set between 0.005-0.025/tooth. The specific parameters should be determined by the user according to the speed of milling machine, the properties of the milling, thickness, number of teeth, milling depth and other factors are determined.

Vc:

P: 70~150, 50~80

K: 80~120

M:70~120

N:200~350

S:20~50

Outer Diameter——Cutting Depth

40mm——3mm

50mm—— 5mm

63mm——8mm

70mm——10mm

75mm——12mm

80mm——15mm

100mm——20mm

125mm——30mm