BB Tools

BB End Mill CNC Solid Carbide Milling Cutter BL3060

BB End Mill CNC Solid Carbide Milling Cutter BL3060

Couldn't load pickup availability

Share

BL3060

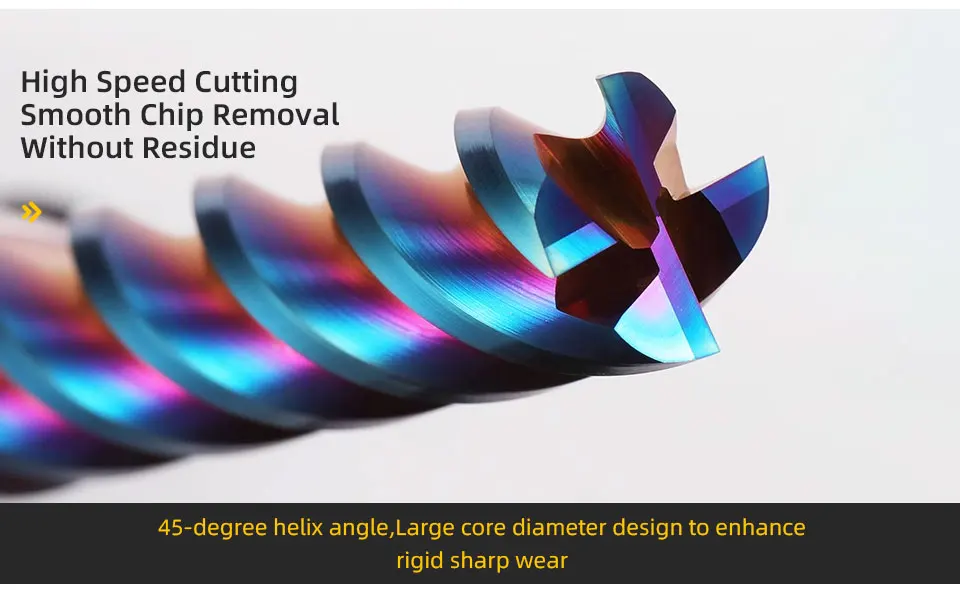

Geometry :45°

(The 45 degree geometry is more suitable for side work.)

-For steel, Stainless steel

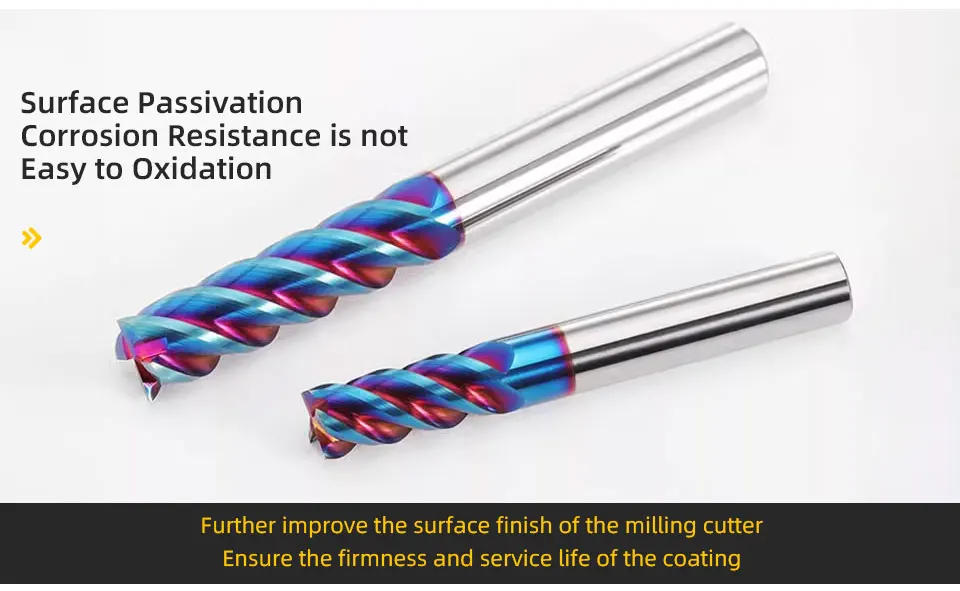

Surface Passivation Corrosion Resistance is not Easy to Oxidation

Further improve the surface finish of the milling cutter Ensure the firmness and service life of the coating

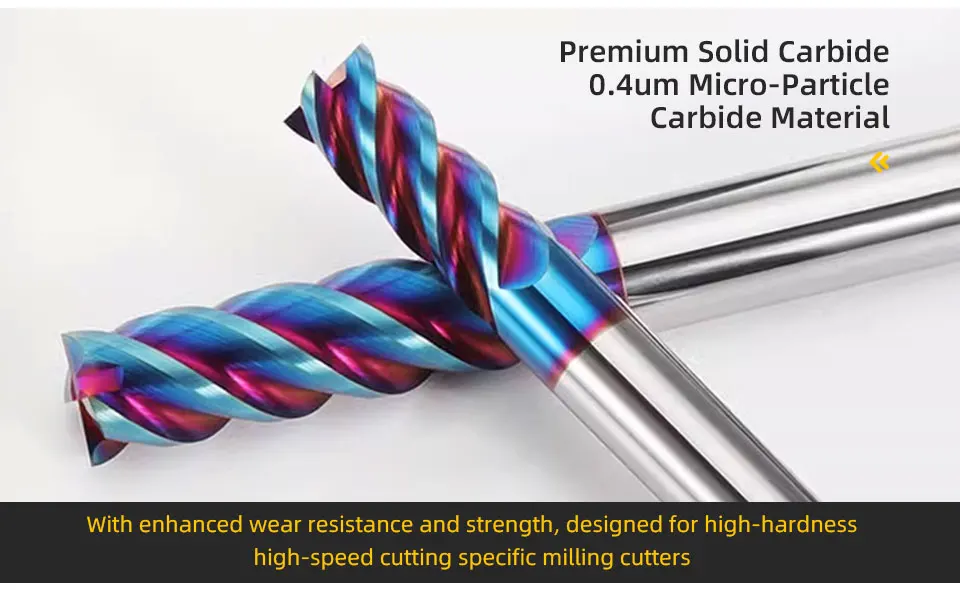

Premium Solid Carbide 0.4um Micro-Particle Carbide Material

With enhanced wear resistance and strength, designed for high-hardness high-speed cutting specific milling cutters

High Speed Cutting Smooth Chip Removal Without Residue

Large core diameter design to enhance rigid sharp wear resistance to improve milling rate

Nano-Coating High Temperature Resistance and Wear Resistance

Using PLAT I T Plating Equipment,Stable Coating Performance

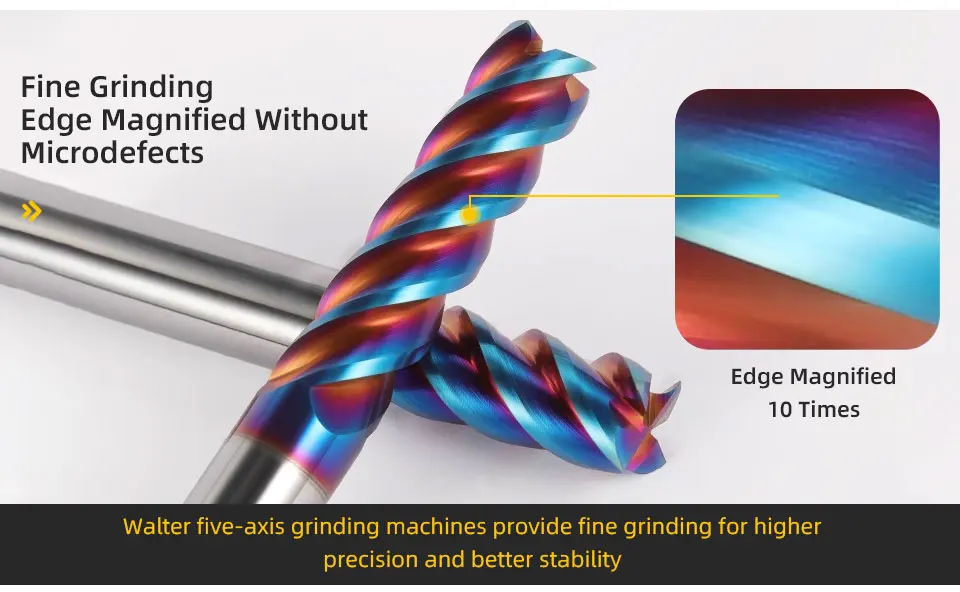

Fine Grinding Edge Magnified Without Microdefects

Walter five-axis grinding machines provide fine grinding for higher precision and better stability

Edge Magnified 10 Times

JIN

-Geometry :38°+40°,unequal spiral angle

-Tizr Coating.

-High hardness and toughness substrate.

-8° Unequal spiral angle, asymmetric design, reduce vibration and improve stability.

-For Stainless steel, titanium alloy, heat-resisting alloy,superalloy, mild steel, brass copper, non-ferrous metals, etc

-Side milling, dynamic milling, trochoidal machining, layer milling.

Suggestions

01.Before using the tool, please measure the tool deviation. If the tool deviation accuracy exceeds 0.01mm, please correct it before cutting

02.The shorter the length of the tool extending out of the chuck, the better. If the tool extends out longer, it is necessary to reduce the speed, feed rate, or cutting amount

03.If abnormal vibration or sound occurs during re cutting, please reduce the speed and cutting amount until the situation improves

04.Steel cooling, preferably of spray type and puff type, can improve the use effect of milling cutter

05.Note: Not suitable for low-speed machines such as bench drills, electric drills, etc